We offer a wide portfolio of magnetising and measuring devices. An extensive range of accessories as well as diverse data acquisition and visualisation options form the basis for customised product packages for a wide variety of tasks.

You are here: Products

Magnetisers and Magnetisation Heads

ELSOMA manufactures customised magnetising systems according to your application and systems dimensioning requirements. A wide product portfolio of magnetising devices, magnetisation heads and magnetising fixtures ranges from small systems to systems for industrial series production. ELSOMA develops and manufactures these high-quality products completely in-house and guarantees you the right application-specific solution for achieving the best results in magnetisation.

The magnetising equipment and magnetisation heads we develop are designed for magnetising and calibrating isotropic and anisotropic magnetic materials. Even highly coercive SmCo or NdFeB components can be magnetised quickly, precisely and energy-efficiently. We are particularly specialised in magnets for sensor and switching applications.

The required magnetising field strength and the size of the workpiece essentially determine the necessary energy of the magnetising device or magnetisation head. A modular design enables the best adaptation to your task. This results in an optimal price-performance ratio.

The systems are suitable for 3-shift use in an automated production environment as well as for use at manual workstations or in the laboratory.

Numerous interfaces, e. g. Ethernet and USB interfaces as welll as optional digital I/O interfaces enable connection to complex process controls and also to automatic process control or quality assurance systems. The standard bulit-in pulse current measurement ensures the required magnetising field strength for each magnetisation.

Magnetisers ELSOMAG® 230 C4 EEM

Highlights:

Functional description:

The ELSOMAG® 230 C4 EEM magnetising unit is a microprocessor-controlled magnetising unit with integrated diagnosis and measurement functionality. It can be used for all permanent magnet materials. It is particularly suitable for magnetising plastic-bonded rare earth magnets. The very short magnetising pulses make it possible to produce multipolar magnets with small pole pitches. For various applications, the flux density of the magnetised magnet after magnetisation as well as the resistance value of an inductive sensor can be checked. Sensors with an integrated Hall sensor can also be tested for function. Faulty parts are indicated. An alphanumeric display provides a plain text output for the measured values and communication with the operator. User guidance is provided via the indicator lights and the display. Via the TCP/IP interface, the limit values for the measurements can be set and, for production control, the measured values can be stored on any PC.

Equipments:

Accessories:

A typical selection of fixtures:

Technical data:

| Pulse energy | Up to 2,400 Ws (depending on expansion stage) | |

| Rated voltage | 230V/50 Hz (+15 % / -10 %) | |

| Rated current | 3 A | |

| Rated power | 0,7 kW | |

| Maximum pulse current | 10.000 A (3 mS) | |

| Charging time of the capacitor | Less than 8 s (at maximum charging voltage) | |

| Magnetising field strength | Depending on the device |

ELSOMAG® IIM2k Impulse Magnetisation Head

Highlights:

Functional description:

The ELSOMAG® IIM2k impulse magnetisation head is a microprocessor-controlled magnetising device with integrated diagnostic and measuring functions. It is particularly suitable for magnetising plastic-and elastomer-bonded hard ferrite magnets. The ability to emit very short magnetising pulses enables the production of multi-pole magnets with pole pitches in the range of 1 to 5 mm.

The short pulses lead to low thermal losses, which in turn, enable fast writing speeds. The magnetisation current level and profile are programmable, offering an intelligent and flexible solution to many different magnetisation tasks. The IIM2k head can be used to write incremental and absolute code tracks on either linear or rotary magnetisation machines.

Equipments:

Highlights:

Technical data:

| Maximum impulse current | 2000 A | |

| Magnetising field (typical) | 1750 kA/m (for 1 mm pole length) | |

| Supply voltage | 30 V | |

| Current consumption (max.) | 5 A | |

| Current consumption (avg.) | ≤ 0.5 A | |

| Impulse duration | 1 µs … 10 µs (resolution 20 ns) | |

| Writing frequency (max.) | 30 Hz (50 Hz under development) | |

| Pole lengths | 1 mm to 5 mm |

Measuring Devices

We develop magnetic measuring devices for the precise measurement and assessment of magnets during incoming or outgoing goods inspections as well as in the service area.

We offer a wide portfolio of measuring technology – from compact handheld devices and fluxmeters to semi- and fully-automatic PC-controlled measuring devices. These products fulfil a wide range of measuring tasks with high accuracy and speed. We calibrate the measuring devices ourselves in our well-equipped measuring laboratory.

Angle-based flux density meter A05

Highlights:

Functional description:

The demand for magnetic angle measuring systems or magnetic rotary encoders is continuously increasing. Consequently, the need for fast, precise measurement technology to check and ensure the quality of the multi-pole magnets used is also increasing.

The flux density of the magnetic field must be measured precisely, productively and cost-effectively on several coded tracks. This is where the CE-marked A05 flux density meter from ELSOMA comes into play for angle-based measurements. The device has a special, highly sensitive and precise 3D sensor chip for detecting all three magnetic field components with just one measurement.

The magnet to be tested is mounted on a drive shaft with a backlash-free preloaded bearing by means of an interchangeable mounting. This shaft is driven by a toothed belt in order to avoid any possible interference field influence from the motor. The angle of rotation of the shaft is measured using a high-resolution optical angle measuring system as a reference measuring system.

The factory-calibrated 3D Hall sensor measures the flux density with a resolution of 10 µT and a measurement uncertainty of less than ±1.25 %.

Individual software solutions for evaluating the measurement results can be implemented and customer-specific adaptations and extensions are possible at any time. The device can be used flexibly for incoming or outgoing goods inspections, as several interfaces simplify integration into automated production systems.

It creates measurement reports in accordance with the new DIN SPEC 91411 “Requirements for the technical representation of magnetic dimensional standards in construction drawings”. Measured variables such as pole length or pole position deviations can be measured and displayed in addition to flux density deviations.

The A05 flux density measuring instrument is ideally suited for measuring tasks at companies in the following fields of application:

Features:

Technical Data:

| Line graduation | 0,025 ° |

| System accuracy | < 0.008 ° |

| Amplitude Resolution | 10 µT (± 1,25 %) |

| Measuring Range | 150 mT |

| Operating voltage | 240 V (50 Hz) |

Angle-based flux density meter A01

Highlights:

Functional description:

The A01 flux density meter for angle-based measurements is used to measure multipole magnetic rings (multipole wheels). During a measurement, the radial, axial or tangential magnetic flux density component can be recorded on up to six tracks and assigned to the angle of rotation position. The visualisation and evaluation of the measurement data is carried out via a PC. ELSOMA offers customised hardware and software solutions for this purpose.

Features:

Technische Daten:

| Angular resolution | 0,2 ° |

| Rotation angle repeatability | < 0,25 ° |

| Amplitude resolution | 0,01 mT |

| Operating voltage (power supply is included) | 12 V (1000 mA) |

Flux density meter C10

Highlights:

Functional description:

The demands on the accuracy of magnetic measuring systems, consisting of magnetic sensors and permanent magnets as measuring standards, are constantly increasing. Rotary encoders or motor feedback systems have to achieve ever higher precision, either in order to be able to position more precisely or to realise better efficiency and lower torque ripples.

These requirements place new demands not only on the sensor technology, but also on the magnets used and consequently on the measurement technology used for incoming and outgoing goods inspections along the value chain.

In the case of disc-shaped or rectangular dipole magnets, as they are very often used for on- and off-axis angle measurement or for switching operations, material inhomogeneities or manufacturing defects can lead to asymmetrical magnetisation or to inhomogeneous magnetic field characteristics. With the C10 flux density measuring device from ELSOMA, such errors are detected much faster than with previous solutions, such as Helmholtz coils.

The axial or radial magnetised component to be tested is typically placed in a specific fixture. A special, highly sensitive and precise 3D sensor chip detects all three magnetic field components with just one measurement. The measuring device provides the user with both the flux density components and the solid angles of the flux density vector. This allows magnetic misalignment angles on magnets to be checked quickly and precisely.

Simple and flexible integration into automated production lines is made possible by the C10 portable flux density meter, which is equipped with a rechargeable battery, via Ethernet and USB interfaces as well as a digital I/O interface. A browser user interface supports quick configuration of the device as well as visualisation of measurement results. Customer-specific software extensions are possible at any time.

An internal data memory simplifies the monitoring of measurement series for quality assurance or incoming goods inspections. These measurement series can be easily retrieved via the network interface.

In addition to the above-mentioned devices with 3D probe, ELSOMA offers a wide range of further axial and transverse measuring probes to expand the measuring device. With the help of these probes, flux densities in the range of 10 µT to 5 T can be measured with a resolution of up to 1 µT and a measuring error of less than 1 %.

The C10 flux density meter is ideally suited for measurement tasks at companies in the following application areas:

Features:

Available probes:

Transversal probe TS5.1D

1D Hall probe for the detection of fields in the range from 10 µT to 5 T Length of the measuring tongue approx. 86 mm, width approx. 4 mm, thickness approx. 0.6 mm

Axial probe AS5.1D

1D Hall probe for the detection of fields in the range from 10 µT to 5 T Length of the measuring tube approx. 100 mm, diameter approx. 6 mm

3D Probe FH2.3D

3D Hall probe for capturing the solid angle of the field vector

Probes for the detection of alternating fields

In preparation

Features:

A typical selection of fixtures:

Technical Data:

| Resolution | 1 μT (in the most sensitive measuring range) |

| Measuring ranges | ±5,00 T / ±2000 mT / ±1200,0 mT / ±400,00 mT / ±100,000 mT |

| Maximum flux density | 5 Tesla |

| Measuring error | 1 % + 3 Digit (ambient temperature 20 °C ± 5 °C) |

| Battery operation | > 5 h |

| Power consumption | Maximum 3 W |

Field strength meter H1-4

Functional description:

Hand-held unit for mains, battery or rechargeable battery operation. Device for measuring magnetic direct and alternating fields with three measuring ranges: 20 mT, 200 mT and 2000 mT. A conversion to the unit kA/m is optionally possible at the factory. The field strength meter H1-4 is a low-cost, electronically measuring and digitally displaying hand-held device.

Available probes:

Technical Data:

Technical Data:

Fluxmeter

We develop measuring devices for magnetic quantities to enable precise measurement and assessment of magnets during incoming or outgoing goods inspections as well as for service tasks.

We offer a wide portfolio of measuring technology – from compact handheld devices to fluxmeters and semi- and fully-automatic PC-controlled measuring devices. These products fulfil a wide range of measuring tasks with high accuracy and speed. We calibrate the measuring devices ourselves in our well-equipped measuring laboratory.

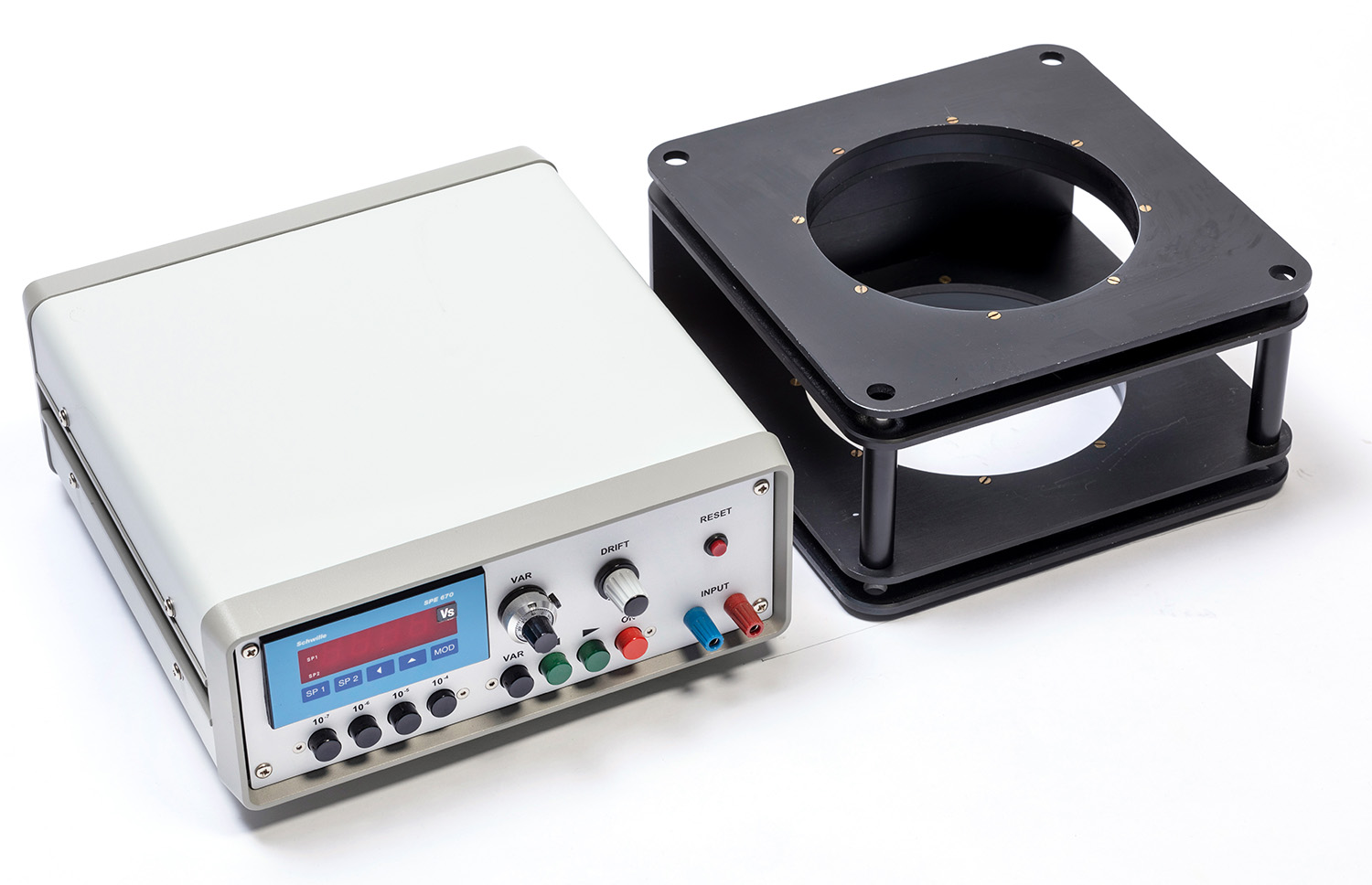

Fluxmeter B2

Functional description:

The Fluxmeter B2 is an electronically integrating, digitally displaying instrument with high sensitivity and low drift. Its versatility allows it to be used in the laboratory as well as in production. All the measuring coils we offer can also be used on this instrument, making the B2 a universally applicable instrument in magnetic measuring technology. The Fluxmeter B2 has four measuring ranges and offers the possibility of continuously adjusting the sensitivity from 10 to 110 % in all measuring ranges by means of adjusters. A coarse adjuster and a fine adjuster are available for drift adjustment. The Fluxmeter B2 has an analogue output for connecting an A/D converter for digital processing of the output signal.

In combination with appropriate measuring coils, the following magnetic quantities, for example, can be measured:

Accessories:

Interfaces:

Technical Data:

| Display | LED digial display with 15 mm digit height, 3 ½ digit, 3 measurements/second, maximum value memory automatic polariy display |

| Measuring ranges [Vs] | 2×10-4 / 2×10-3 / 2×10-2 / 2×10-1 |

| Measuring constant [Vs/Digit] | 10-7 / 10-6 / 10-5 / 10-4 x (1 + Rs:104 Ω) |

| Integration constants [s] | 10-3 / 10-2 / 10-1 / 10 |

| Measuring accuracy | ≥ 0,6 % |

| Reproducibility | ≥ 0,3 % |

| dφ/dt max. [Vs/ms] | 0,06 |

| Drift [Vs/min] | ≤ 3 x 10-6 |

| Input | Ri= 104 Ω |

| Output | Analogue output ± 199.9 mV corresponding to 1999dDigit, connection for analogue display, or similar |

| Power supply | Mains connection 230 Volt, 50 Hz, ca. 5 VA |

| Interfaces | RS 232 (V24), window comparator with relay output |

| Dimensions | 260 mm x 110 mm x 265 mm (W x H x D) |

| Weight | Approx. 2.5 kg |

ELSOMA GmbH

Kurzer Morgen 7 | D-58239 Schwerte

Sie interessieren sich für unsere Produkte?

Sie möchten mit uns gemeinsam nach einer Lösung

Ihrer Aufgabe suchen?

Dann schreiben Sie uns.

Wir freuen uns auf einen konstruktiven Austausch!

Are you interested in our products?

Would you like to work with us to find a solution to your problem? Then write to us.

We look forward to a constructive exchange!